Piggery(Pig farming)

Local names in Kenya (Nguruwe)

Overview

Overview

Pig production is, along with poultry production, the fastest growing livestock sector worldwide and this trend is expected to continue over the coming years. Increasing demand, limited land requirement, a shorter life cycle with higher return rates and advantageous feed efficiency are key reasons for this development.

Most Farmers engage in pig production as a business with the aim of providing meat (pork) and other pig products to the consumer; earning an income through sale of pigs, meat, and to a limited extent compost. To run a successful pig production business, the farmer has to increase the number of healthy piglets weaned per Sow per year and minimize feed costs while ensuring consistent adequate performance.

A variety of pig production systems currently operate in Kenya’s pig sector. There are large intensive commercial pig farms, medium scale commercial farms, small-scale commercial farms and free range traditional systems (including scavenging and roaming) in Western Kenya, Nyanza and the suburban slum areas of the major cities and towns. The small scale farmers, who make up about 70% of pig producers in Kenya, are estimated to be 5000. Small scale farmers are characterized by 5-100 pigs and are spread in Central, Rift Valley, Eastern, North Rift, Nyanza and parts of Western Kenya.

There are a few smallholder intensive pig-raising systems in Busia, Bungoma and parts of Kisumu in Western and Nyanza respectively.

The most common pig production system in western Kenya (Nyanza and Western provinces) is the traditional/free range. This system is characterized by low offtake, low reproductive performance, minimal supplementary feeding or health care, lack of proper housing, high mortality rates and high levels of inbreeding. In spite of this, most farmers still opt for the system (traditional) rather than intensive farming because of the high input costs associated with the latter.

The expanding pig production sector in Kenya is facing diverse challenges, namely: poor breeds; poor feeding and husbandry practices; limited technical knowledge and skills; limited-quality breeding stock and artificial insemination services; low quality-high cost feeds; and inability to service volume and quality demands of the market.

Feed millers also face challenges of sourcing high quality raw materials and low level of technology in production. These challenges have led to high feed prices beyond the reach of many farmers. This has resulted in farmers mixing their own feed rations from locally available raw materials.

Despite these challenges, the demand for pork and other pork products is rapidly expanding. Irrespective of the type of market, current demand for pork far outstrips supply, hence the need for increased production.

The existing gaps and challenges present business opportunities in production, input supply, feed, and processing in the whole pork value chain.

This document is prepared for knowledge and information on improved pig farming practices with the aim of increasing household incomes. It provides general guidance on modern pig farming and is in no means exhaustive.

Farmers interested in piggery enterprise need to engage in pig production as a business with the aim of earning an income through sale of pigs, meat (pork) and other pig products.

A farmer intending to start a piggery enterprise should consider the following issues;

- Working capital. This is the amount of money required to set up the piggery project. The amount is dependent on the unit size one intends to operate. The capital is needed to construct the sties, buy equipment and breeding stock, pay for feed, drugs and labor for the initial phase of the business.

- Knowledge and skills. . In order for the farmer to avoid making costly mistakes in the running of the pig production enterprise he should receive training on how to successfully manage a pig production enterprise.

- Breeding stock: The output of a unit can be limited by the quality of breeding stock. Inferior breeding stock results in an inefficient utilization of feed and space. Farmers must be prepared to pay high prices for quality stock. Poor quality breeding stock may be cheaper in the short term but in the long run they will be expensive.

- Market: Farmers have to identify the market for their pigs before they start producing them. Farmers should desist from the practice of hunting around for a market when their pigs are ready for sale. An important point to consider when choosing a market is the market price and the distance to the market. If the distance to the market is long the project will incur high transport costs and hence will be less viable.

- Water: Water should be of the right quantity and quality. Inadequate water supply depresses the growth rate of the pigs. Lactating sows need a lot of water for milk production.

- Housing The pigsties should be constructed in a way that will allow the stockman to carry out his daily duties with ease. Poor housing designs can lead to disproportionate food sharing, inefficient utilization of space, feed wastage and poor performance of the pigs among other things.

- Feed availability: Feeds account for about 80% of the production costs on a pig production enterprise. A guaranteed supply of feed is a prerequisite for the successful operation of a piggery project.

- Technology to useThere are many technologies for piggery production. The common ones are (a) the free range system, (b) intensive pig production system and (c) the semi-intensive pig production system. The choice of which one to use depends on the skills and resources available to the farmer.

In the free-range system pigs are allowed to scavenge or wander freely and pick up food when and where they can get it. The system requires little investment and management; and there is minimum disease control. They may receive supplementary feeds such as kitchen wastes, farm by-products, and others. Local breeds of pigs pre-dominate the free range system because they are more highly adapted.

In the Semi-Intensive system, the animals are restricted to a limited area and the farmer feeds them. Once in a while, the pigs are allowed into a larger area to graze, wallow and exercise. The animals are fed on kitchen wastes, food by-products, among others and some level of managerial skills are required.

In the intensive production system, pigs are reared in an encloser (house). Housing is more modern and provides shade, pen space, feed and water facilities to meet requirements of the pigs. Feeding, management and disease control are more modern. Breeds reared are exotic or cross breeds.

To be profitable, a pig production enterprise should use Sows and Boars from high quality improved breeds.

In selecting the right pigs for breeding, a farmer should consider:

- Selecting good gilts from Sows of a superior breed that wean 9-10 piglets per litter and that are known to be good mothers.

- Selected gilts should have at least 12-14 teats so that a large litter can be easily nursed.

- Gilts should be healthy with strong legs and well developed body and thigh muscles.

- Starting with about 1-2 gilts/Sows and progress as more experience and skill is gained.

The following are the most common pig breeds in Kenya and their characteristics;

Breed: Large White

Performance traits; White with erect ears, good mothering ability, produces many litters, fast growing and fairly hardy.

Maturity weight (kg): Male 310 – 400; Female: 250 – 330.

Breed: Landrace

Performance traits; White, lopped ears, fast growth rate, high quality carcass.

Maturity weight (kg: Male 310 – 400; Female:250 – 330.

Breed: Hampshire

Performance traits; Black with white markings, good carcass quality, high meat yield.

Maturity weight (kg: Male 300 Female 250

Breed: Duroc – jersey

Performance traits; Dark brown, fast growth rate, good mothering ability. It is tolerant to stress and is adaptable to various environmental conditions.

Maturity weight (kg: Male 300; Female 250.

Breed: Crosses

Performance traits; Crosses of Large white and Landrace are common. They are very good when used as Sows for breeding

Maturity weight (kg: 200-300

Breed: Local pigs

Performance traits; Different colors, hardiness, adaptability, large litters

Maturity weight (kg: 100-150

The purpose of housing pigs is to provide a suitable environment that will enable the pig to grow or breed optimally.

Proper house enables easy management and ensures more piglets are reared to market weight. Pig housing should aim at:

- Protecting the pig from extreme weather (rain, cold, sun).

- Protecting the pig against theft and other predators.

- Minimizing overcrowding, waste of feed and water.

- Avoiding conditions that predispose the pig to diseases.9

- Enabling easy cleaning and effective disposal of effluent.

- Ensuring easy movement of the stockman.

In the constructing a pig house, the farmer should consider the location, the orientation and the floor space requirements:

- The Location: The site for a pig house should be easy to drain and not water logged. It should be a significant distance away from residences and public walk ways and should be easily accessible by

- The Orientation: The house should face north-south to avoid direct sun into the pens. A simple demonstration is for the trainer to stand and face the direction where the sun rises (the east). Your left arm points to the north and the right arm to the south. The north-south direction becomes the front or back view of your pig house.

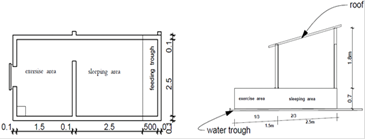

- Floor space requirements: A housing unit should not be overcrowded as this will lead to discomfort, increased susceptibility to disease, Poor weight gain and increased cases of fighting.

Pig space is calculated according to age and production stage, taking into account feeding, watering, sleeping and dung area requirements.

There are three types and sizes of pig pens:

- Farrowing pen for the sow to give birth until weaning.

- Pregnant sow pen designed for pregnant sows only.

- Group pens for weaners, growers or fatteners—designed for growers and finishing pigs.

Modern shed for pigs

Ground plan and side elevation of a grower’s pen

Farrowing pen

Components of a pig housing unit

The Roof: The roof should be made of material that protects pig from rain and direct sunlight. It should be made from locally available materials such as dry thatching grass, polythene sheets, papyrus mats placed over polythene sheets or iron sheets. The roof should be at least three meters above the ground to create a cool environment.

The Walls: The walls should allow for maximum air circulation. Use either bricks or timber off cuts. The off cuts should be nailed on the inside part of the house to prevent the pig from pushing against it easily. The wall should be well plastered.

The Floor: the floor of the pig house should be made of hard reinforced concrete that has a rough surface to avoid slipping of the pigs.

Feed and water troughs

- The feed and water troughs should be placed on opposite sides so that the pigs can exercise as they move from one trough to another.

- water troughs should be shifted regularly to avoid over wetting the same spot and to create more room for exercise after the animals have fed and drunk water.

- Each pig should be allowed a space of 30cm in a feed trough.

- water trough should be at least 30cm in height.

Feeds supply nutrients which are required for body maintenance, growth and reproduction. Proper feeds ensure faster growth and high fertility rates.

There are six classes of nutrients required by the pig, namely, energy, protein, vitamins, minerals, lipids and water.

Energy: Provides the body system with the power to function. The energy requirement of the pig is supplied by carbohydrates and fats. The main sources of carbohydrates are cereals (Maize

Sorghum, Millet, Wheat), Cereal processing by products (Maize bran, Wheat bran, Rice bran), root and tuber crops, and fruits. Fats commonly used in pig feeds include groundnuts and soybeans oils, among others. Animal fat is also a good source of energy. The pig requires very small amount of linoleic acid, an essential fatty acid required for the body’s normal functioning.

Protein: Provides the primary blocks for body building and repair. Most commonly used protein containing feedstuffs are Fish meal, Blood meal, Poultry and fish processing wastes, Soybeans, Beans Groundnuts, Cotton seed cake, Sunflower seed cake.

Minerals: Minerals are required for strong bones and normal body function. The minerals required in sizeable quantities are calcium, phosphorus, sodium, and chlorine. Iron is very important to the piglet. Common sources of minerals include: lake shells, bone ash, common salt, brown salt, soil and commercial vitamin-mineral premix. Bone meal, oyster shell and limestone are the most common sources of Calcium and Phosphorus in pig rations.

Vitamins are required for maintenance of normal health. Common sources of vitamins for pigs include green leaves and vegetables.

Water: Sixty-five percent of the pig’s body is water. A Sow needs 20 liters of drinking water daily. The pig requires water to enable all body functions such as digestion, excretion, blood circulation and maintenance of body temperature. Lack of water quickly leads to a rise in body temperature and death; less water will have a major effect on food intake and pig performance.

Feed types and quality characteristics

Creep feed (Pig Creep Pellets):

- This is introduced to piglets from the third week up to 8 weeks when they are weaned.

- Creep feed is given to supplement Sow milk

- It must be high in protein (20-22%) and , highly digestible

Weaner feed:

- This is fed to pigs after weaning from 2-4 month

- It contains 14-20% protein

Grower feed:

- This is feed to pigs that are between 4-6 months

- It is given to breeding animals (gilts, Sows and Boars)

- It contains 14-16% protein

Pig Finisher meal:

- It is given to animals after 6 months

- It contains 11-13% protein

Daily Feed requirements

Dry/pregnant Sows and Gilts: for dry sows and gilts give 2.5kg/day of sow and weaner meal. Give extra 1kg/day one week before serving gilts and sows and one week after service. Give lactating sows 2.5 kg/day of sow and weaner meal for maintenance and 0.25 kg/day extra for each piglet being suckled.

Boars: Give boars 2.0 kg/day. If the boar is regularly used give it 2.5 kg/day.

Piglets: Give creep pellets i.e. 0.5 - 1.00 kg/day from day 7 up to weaning time (21 days) per piglet. The feed should be mixed with sow and weaner meal the last one week before weaning.

Feeding rates by age and expected body weight gain

Age (wks) Body Weight (kg) Feed kg /day Feed type

8-10 12-15 0.66 Sow &weaner/starter

10-12 15-20 1.0 Sow &weaner/grower

12-16 20-40 2.0 Sow &weaner/grower

16-18 40-50 2.5 Finnisher

18-24 50-84 3.0 Finnisher

24-28 84-105 3.5 Finnisher

Feeding during pregnancy

- For the first two and a half months of pregnancy the daily allowance for the Sow is 3 Kgs

- The feed intake should be increased gradually by 0.25 kg in the 11th week of pregnancy through to 0.75 kg in the last week of pregnancy. This is called Steaming up.

- Do not over feed. Fat Sows tend to have problems at farrowing.

- A day before farrowing, cut the feed down by a half to avoid constipation

Feeding Lactating Sow and her piglets

- The basic maintenance ration is 3 kg of Sow meal.

- Add 0.25 kg for every piglet in her litter.

- Divide the feed in two equal parts. Feed one part morning and the other in the afternoon.

- Feed greens and roughage in between the two meals

- From the 6th until the 8th week of lactation, reduce the daily allowance gradually, so that by weaning she is getting just 3 kg.

- Inject piglets with iron on the second or third day after birth.

- Provide creep feed to the piglets 10 days after birth.

Feeding pigs at growing and finishing stages

- Growing stage is identified as the stage from weaning (12 kg) to about 5 months (60 kg).

- The aim is to maximize lean muscle production and minimize fat deposition

- Over feeding increases the proportion of fat and this may be un-acceptable to the market.

- Each pig should receive feed equivalent to 4% of its body weight. For example, if a pig weighs 60 kg, it will get 60 x 0.04 = 2.4 kg daily.

- Divide the feed in two equal meals to be given in the morning and afternoon.

- Measure the pigs every 7 days to determine new feed ration corresponding to weight gained the previous week.

Feed Sources

Feeds can either be bought as commercial feeds from feed manufacturers or mixed locally by farmer. If mixed locally, the farmer should remember that feeding pigs for optimum production requires that feedstuffs be combined in proportionate amounts that will provide the quantities of nutrients needed by the animals.

(i)commercial feeds sources

Feed manufacturers are not specialised in pig feed but provide feed for all types of livestock; pig feed accounts for 3% of feed output from millers.

Most feed manufacturers are located around Nairobi, Nakuru and Thika regions. Major millers include; Unga Feeds, Chania Feeds, Pembe, Isinya Feeds, Ngae Feeds, and Farmers Choice.

The main pig feeds types manufactured are Sow &Weaners, Pig Finisher and creep feeds. Sow &Weaner meal and pig finisher account for 98% of manufactured pig feed. Manufactured feed is deemed too expensive by farmers, a challenge that was compounded by VAT of 16% levied on raw materials for feed making.

Key ingredients used by millers in animal feed are cereals (maize, sorghum), dagaa fish (Omena) and cakes (sunflower, cotton seed, copra) and vitamins. Vitamins and minerals for pig premixes are mainly imported.

(ii)Local feed resources

The high cost of feeds has seen mushrooming of businesses providing cheap but poor quality feeds. This has forced most medium and small scale producers to innovate around feed making. Farmers are increasingly producing their own feed from raw materials purchased and mixed at the farm and supplemented with the compounded feeds to cut costs. Fermented sweet potato vines and tubers, Lucerne, cabbages, kales, garden weeds, maize stovers, hotel/school swill, brewers waste are commonly utilised by farmers in feed making. Large scale farms generally use compounded feeds from their mills.

The main resources for feeding pigs are cotton seed cake and prairie meal, with gluten feed as a source of protein. Pigs are in competition with humans for maize, their main source of energy. Other energy sources include milled by-products such as the bran from wheat, maize and rice, along with maize grain, wheat grain and semi-refined oil. Limestone is the main local mineral source. Although there is no shortage of animal feed in Kenya, the cost is high and in some areas quality is not the best. Concentrates, for instance, are available but very expensive.

Use of crop residues / by-products

Many commercial pig farmers also grow food crops, the surplus produce or by-products which can be used to feed the pigs. This food source plays an important role in pig feeding, especially in free range and small-scale production systems. Crops and by-products include sweet potato vines, kales, cabbages, Napier grass, sugar cane cuttings, sugar cane tops, garden weeds, mangoes, tomatoes, oranges, avocadoes, peelings and market by products/waste. The use of feeds such as cereal residues, cassava and potatoes has been shown to save up to 20 percent on feed costs for growing pigs and 50 percent for breeding pigs. Other by-products include brewers waste, rumen contents and slaughter blood from slaughter slabs. These are either given to the pigs as is, or mixed with kitchen leftovers. Some farmers also cook the blood and mix it with ugali (cooked maize meal). Another source of feedstuffs for pigs is swill from schools, hotels and government institutions. Farmers around these institutions collect the leftovers to feed their pigs. Some institutions, especially schools and prisons, feed their own pigs with the available kitchen leftovers. The drawbacks are that the safety, amount and quality of feed is not guaranteed and pigs fed inadequate and unbalanced diets will have low weight gains.

Management of pigs

Running a successful pig production enterprise requires that the farmer has to increase the number of healthy piglets weaned per Sow per year and minimize feed costs while ensuring consistent adequate performance.

Selection of Breeding Boar

It is extremely important to select a good boar since it contributes half the quality of the herd. Areas to be consider while selecting breeding Boar include:

- Boar to have sound feet with good, full hams, uniform curve at the back and of good length.

- Boar to be selected from sows, which wean 8 -10 or more piglets per litter and are known to be good mothers.

- Boar to be selected from the herd which is having normal sex organs, active, healthy and strong.

- Selection to be done before castration i.e. at 4 weeks. Select biggest from the litter.

- Boar must be at least 8 months old at first service.

A farmer can use one or both of the following methods in service;

- Pen mating. In this method, one Boar is reared with a group of 8-10 Sows. The Boar is left to mate with Sows as and when they come on heat.

- Hand mating. In this system, a Boar is kept in a separate pen. Sows on heat are taken to it for service. It ensures that each Sow is mated twice and the exact breeding date is known.

Management of the Boar

- Young Boars should be reared in groups so that they can develop normal sexual behavior.

- Young Boars should not be underfed, otherwise their libido and fertility will be reduced. Depending on the age and condition, a young Boar should be fed 2-3 kg of Sow and Weaner meal daily.

Selection of Breeding Gilt

Areas to be consider while selecting breeding Gilt:

- Gilts selected to have at least 12 teats so as to accommodate a large litter.

- Gilts to be selected from sows, which wean 9 -10 or more piglets per litter and are known to be good mothers and first farrowing at one year of age and farrowing interval of seven month.

- Select breeding gilts at weaning period, further selection should be done 5-6 months of age.

- Select fast growing weaners. These will likely consume less feed per unit live weight gain. Thus less costly to keep.

- Select gilts which have developed hams and comparatively light heads.

- The selected gilts should have good body confirmation i.e. strong legs, sound feet etc.

- Gilt should not select for breeding purpose having supernumerary and inverted teats, and fat deposited at the base of the teats. Guilt must be at least 8 months old at first service.

Management of the gilt /Sow.

- Well managed gilts reach puberty between 4.5-6 months. They should be exposed to a Boar at 4 months. Boar smell and noise is known to induce puberty.

- Delay serving gilts/Sows until they are 7 to 8 months old. Serving young Sows impairs their development and productivity.

- Feed adequate quantities of well-balanced diet to Sows for maximum production and delivery of healthy piglets.

Prior to serving, a farmer should:

- Allow her a lot of exercise

- Increase feed allowance (flush) to maximize the number of eggs released. Return to the normal ration after mating.

- Observe for signs of heat at least twice a day

Signs of a Sow on heat:

- Aggressively seeking out a Boar

- Restlessness

- Vulva swells and reddens

- Frequent urination and vaginal mucus discharge

- Mounting others or when mounted it stands still

- When pressed on the back by the farmer they stand still.

A sow or gilt should be inseminated or mated with a boar within 13-20 hours of manifestation of the symptoms of heat.

When to serve a Sow on heat.

The farmer should strictly observe the AM-PM rule below:

- Sows observed on heat in the morning (AM) should be mated in the evening of the same day (PM).

- Sows detected in the evening (PM) should be mated in the morning (AM) of the following day. Sow should be brought back for a second mating twelve hours after the first mating.

If a sow does no conceive after first mating, it usually comes in heat in another 18-25 days.

Management during pregnancy

- Ensure good health by maintaining proper hygiene and administering multivitamins and deworming.

- Provide enough space and keep the bedding moist all the time.

- Do not keep more than 10 Sows in a pen.

- A pregnant Sow must not travel long distance.

- Avoid excessive feeding which makes them too fat. Fat pigs experience difficulties during farrowing.

- Farrowing is expected 114 +/- 3 (three months, 3 weeks and 3 days) days from when the Sow was mated.

Signs of farrowing:

- The Sow becomes restless about 24 hours before farrowing.

- There is a distinct swelling of the vulva

- The teats are turgid and produce small amounts of milk when pressed

- The Sow begins to dig a hole in the litter as it builds a nest

- It lies down and abdominal contractions may be noticed

- A bloody fluid will come out from the vulva.

Management during and immediately after farrowing

Although most Sows farrow on their own, others may need to be assisted under the following circumstances;

- When piglets are born with membranes. Such pigs will not start breathing. To induce breathing, the farmer has to clear the membranes away, massage the chest area of the piglet gently while holding the hind legs.

- Sows may kill the piglets by lying on them. Remove the piglets to safety or give “kiss of life” to the piglet if it has been slept on to start breathing.

- Some piglets may be too weak to suckle or fail to locate a teat; show and guide such piglets to a teat.

- The length of the navel cord may be excessively long. Shorten such navel cord by cutting off a piece, and dip the end attached to the piglet in an iodine solution to prevent infection.

Important events in sow management after farrowing;

- First week after weaning, breed the Sow (put the Sow to the Boar)

- Two weeks before farrowing, treat for internal and external parasites

- Cull Sow at weaning on basis of productivity, temperament and other economic factors

- Record events; record the number of piglets born alive and those born dead. Record the number of female and male piglets. After identification, weigh the piglets and record the weight of the litter at birth.

- At 3 weeks of age weigh the piglets again. Weight at 3 weeks of age gives an indication of the milk producing ability of the Sow and her mothering ability.

Management of piglets

- Make sure all piglets are nursing once farrowing is completed. Any excess piglets for the number of functional teats should be transferred to another Sow. If there is no other Sow, bottle feed the piglet with cow’s milk sweetened with glucose. Transfer at 3-4 days of age while masking odours.

- Clip the teeth within 24 hours to avoid damage of sow’s udder when suckling.

- cut the navel cord leaving about 2.5 - 3.5cm of which should be dipped in a 7% iodine solution to prevent infection.

- After 2-3 days treat piglets for anemia with 2-3ml of injectable iron.

- Provide creep feed at 7 days of age. Change feed daily. Treat with iron again after 2 weeks.

- Deworm after 3-5 weeks and then move Sow and piglets to nursery. If litters are mixed in a nursery, litters should not be more than one week difference in age and do not mix more than four litters per pen.

- Identify the pigs by giving them names or numbers using tattoos, ear tags and ear notching.

- Wean at 56 days (8 weeks). Remember to remove the Sow from the piglets and not vice versa.

- Deworm piglets regularly. Spray them for lice and mange mites prior to moving them out of nursery at 7-8 weeks.

- Replace the Sow after the 6th litter or after 4-5 years of age. If its production is still good, leave it until its production falls below the average of the herd.

- Drench with antihelminths to protect them from internal parasites.

- Castrate the male pigs which are not suitable for breeding on the 3rd week.

- Wean young pigs on the 8th week when they are 14– 20 kg. Weaners should be put in groups of 10 – 12 according to weaning weights.

- Proper management of piglets can reduce losses by avoiding the most common causes of piglet deaths which include:

- Suffocation - death caused when the mother lies on the piglets. This can be reduced by building a creep area for the piglets. Sows should be selected for good mothering ability to enhance high piglet survival rates.

- Cold - especially in the first 2 to 3 weeks of life since they have insufficient fat layer to protect them. To keep them warm, provide beddings (dry grass or wood shavings) in the resting area and artificial heating such as infra-red bulbs.

Castration

Male piglets are castrated when they are not to be used as Boars. This makes them docile for easy handling. Castration also removes the male smell from their meat. Castration should be done early before piglets grow to 3 weeks.

Fostering piglets to a Sow.

This involves giving piglets to a Sow other than its own mother. To ensure that the foster Sow does not recognize and reject the fostered piglets, cover the smell of the piglets by:

- Smearing all the piglets including her own piglets with a strong smelling substance like iodine

- Soaking all the piglets thoroughly in a salt solution.

Move the affected piglets to the foster Sow, before they are three days old. Make sure they have received colostrum from their mother before transferring them.

Weaning.

This is the process of separating the Sow from the piglets or removing the piglets from suckling the Sow’s milk. To avoid exposing the weaners to undue stress, remove the Sow from the farrowing pen and leave the piglets in the pen they are used to for some time. Weaning should be done gradually, probably over a four day period. Cut back the daily feed allowance to just 3 kg. This helps to dry the Sow off conveniently.

Rebreeding the Sow after weaning. A healthy well-fed Sow will come to heat within 4 to 7 days after weaning. A farmer should observe such a Sow at least twice a day for signs of heat.

Culling

Sows that are difficult to get in-pig (pregnant) or which only manage to rear small litters should be sold off. Other reasons for culling sows are; frequent abortions, lameness, old age, disease and lack of milk.

Boars which are infertile or moderately infertile should be culled. Boars usually have a maximum working life of between 18 and 24 months. This means they should be replaced when they are 30 to 36 months old.

Male piglets are castrated to prevent their meat from boar taint. Castration also makes them more manageable when they become sexually mature.

Key targets in piggery management:

In summary, the following are the key targets a farmer should strive to achieve in piggery management:

- Reproduction rate – Each Sow should produce 10-11 piglets born alive per litter.

- A Sow should have at least 2 litters each year – i.e. 20-22 pigs born alive per Sow each year.

- Survival rate – At least 85% of pigs born alive should be reared to weaning i.e 17-19 piglets weaned per Sow each year.

- Growth rate – Aim at 90kg live weight in 170 days with a carcass yield of 77% or 500gm/day over a life time.

- Aim at achieving a food conversion efficiency of 3.5kg.

- Aim at marketing the pigs for slaughter as porkers at the age of 4-6 months when they will have attained market weight 65-100kg.

- Strive to ensure a production life span of at most 5 years for the Sows.

Monitoring the growth of your pigs

Monitor the growth of your pigs regularly. This is important in indicating how the pig is growing. Give the pig adequate feed and detect any signs of ill health and treat it. A farmer should have a record book to capture information such as weekly weight on individual pigs, amount of feeds given, diseases and pest incidences, for each pig. The record book should also indicate how the feed was split between the morning and evening schedules.

Take measurements of the pigs weekly using girth method or weighing scale method. Plot the growth of the pigs on a convenient surface so you can spot out any slowdown.

(i)The weighing scale method: A commercial weighing scale is the most convenient and accurate method for recording pig weights. As the animals get bigger, weighing with a weighing scale gets

more difficult. At an appropriate stage, a farmers should shift to the girth method for weighing mature pigs.

(ii)The girth method: A farmer can use the girth only method to get the approximate weight of the pig. If we take the girth measurement in cm, the weight (kg) will be calculated by:

Weight (kg) = ({4.07 x girth} - 333)

If any pig appears to slow down, examine the pig in detail to find out the cause of the slow growth. If necessary feed the pig separately. Treat the pig promptly if there is any signs of ill health.

Major Parasites are;

- Mange mite

- Lice

- Jiggers

- Fleas

Major diseases are;

- African Swine Fever

- Gastroenteritis

- Foot and Mouth disease

- Swine dysentery

- Swine erysipelas

- Anthrax

- Pneumonia

For good productivity and profitability, pigs should be kept as healthy as possible.

A healthy pig will:

- Move about steadily

- Breath steadily and easily

- Eat well

- Have a loose shiny skin

- Have bright eyes and moist nose

A sick pig will show :

- Loss of appetite

- Difficult and abnormal breathing

- Dullness

- Defecation of excessively hard or watery feaces. Feaces may be blood stained or contaminated with worms.

- High temperature (fever) and abnormal heart beat

- Rough hair coat and loss of condition

- Coughing, lameness, diarrhea, nasal discharge, abortion and skin discoloration

- Rubbing against hard objects (signs of irritation or itching).

The following are the Common parasite/’ diseases of pigs and their management practices:

|

parasite |

Clinical signs |

Control and Treatment |

|

Worms |

Anaemia, loss of condition. Weight loss in later stages. Poor growth; Rough grey hair coat; Swollen belly Emaciation; Anorexia in advanced stages. |

Deworm pigs every three months after weaning with Antihelmintics like Levamisol and Piperazine |

|

Mange |

Mange is caused by small parasites called mites that live in the skin. They provoke severe itching and irritation leading to scratching especially at mid-day; Scabs appear on the skin, wrinkling and hardening of the skin; loss of the hair and shaking of the head if the ear is affected. |

Recommended control products are: ivermectin (1% injectable), or malathion (1%) spray at recommended dosage levels. clean and disinfect the pen; Spray the animals with cattle dip. |

|

Lice |

These blood suckers cause irritation of the skin. Lice will be seen in the folds of the skin especially in the neck and at the base of the ears.

Itching skin may show red spots or bite wounds. Thick skin and rough hair coat. Anaemia in severe cases especially in piglets. |

Routine spraying with insecticides like Ivomec tactic-acaricide; benzene exachloride is a very effective remedy against lice. repeat after 7 days. General cleanlines. |

|

Myiasis |

Disease caused by flies, which lay eggs in the wounds. Infected wounds look very wet and dirty and the edges covered with a grey mass which are the eggs of flies. |

Clean the wound daily with water and disinfectant then apply insecticide on wound to cover edges too. |

|

Parakeratosis |

Similar signs to those of mange but with no itching and scratching |

Give zinc Formulations like zinc sulphate in the diet. |

|

Disease |

Clinical signs |

Control and Treatment |

|

African swine fever |

Fever, dullness and huddling together; loss of appetite, staggering gait/ circling coughing, discolouration of skin to bluish, fluid eye and nose discharges, vomiting and diarrhea. |

Restrict movement of pigs or meat from affected areas.

Slaughter of all pigs on the affected farm followed by disinfection. |

|

Foot and Mouth Disease |

Fever and stringy salivaion; vesicles in the inner cheek, gums, tongue and sometimes on the lips; Lameness due to pain. |

Vaccination Isolation of sick animals. |

|

|

|

|

|

Swine Dysentery

|

scours, dehydration and death, especially in baby pigs. |

avoid stressful condition for pigs; administer antibiotic to sick pigs orally; ensure proper feeding of balanced ration. Piglets must be given colostrum. |

|

Salmonellosis |

It is a disease of the intestinal tract caused by Salmonella bacteria. Pigs of about two months are most affected. Heavy worm infection triggers it off. |

good management, practice high level of hygiene and sanitation and provide antibiotics and sulphur drugs in feed. |

|

Swine erysipelas |

Sudden death, loss of appetite, red and bluish appearance of the skin and ears; Diamond shaped skin lesions which may become necrotic. |

Clean the pen and disinfect. Treat with penicillin. |

|

Mastitis, Metritis and Agalactia ( MMA ) |

Sow fails to release milk after farrowing. The udder may be swollen and painful. |

Good hygiene in the pig pen Use antibiotics and oxytocin |

|

|

|

|

|

Piglet anaemia |

Signs appear mostly in piglets of 3 weeks of age, pale mucous membranes and skin, dullness and diarrhea. |

Put red soil in pig pen or give iron injection to young piglets. |

The ability to market pigs at the right time is a major determining factor to the success of commercial pig production.

There are basically, three types of market outlets for pigs or pork in Kenya, as listed below:

(i) Animal trade markets

There are livestock markets in all areas of the country but, unlike for other livestock, there are no live pig markets in Kenya. Animals brought to market include cattle, sheep, goats, donkeys and camels but not pigs. Live pigs are traded on farmers’ premises. The farmer calls the trader, or traders visit the farmers, especially in the traditional free range systems where traders move from village to village looking for pigs.

Farmer’s Choice Limited does not buy live pigs. Farmers transport live pigs to the factory and are paid according to cold dressed weight (CDW) after slaughter.

Farmers buying weaner pigs get them from other farmers whose sows have farrowed. The few breeders provide breeding stock. The National Pig Breeding Unit at KARI, Naivasha used to sell breeding stock to farmers regularly but breeding was suspended in 2008. There is hope that it will be revived but for the time being there is no organized or regular sale of

stock. In the meantime, there is a drive to organize pig farmers into groups and cooperatives able to organize and manage live pig trade markets.

(ii) Slaughtering facilities (Abattoirs)

There are five main slaughter facilities in Kenya.

- Farmers’ Choice with a capacity of 400 pigs a day,

- Kenol-Kabati slaughter house in Thika with capacity of 30 pigs per day;

- Ndumboini Slaughter house in Kabete with capacity of 50 pigs per day;

- Lyntano slaughter house in Nairobi with capacity is 8 pigs per day; and

- London slaughter house in Nakuru with capacity of 8 pigs per day.

- Pig slaughter in other producing regions is done mainly in localised abattoirs but with very limited capacity. However, it is only Farmers Choice that adheres to international quality standards such as Hazard Analysis Critical Control Point (HACCP), BVQI (Bureau VERITAS Quality International), ISO and Total Quality Management standards. It is therefore the only abattoir exporting pork and pork products from Kenya.

(iii) Processors

The large pork processors are located in Nairobi area and major cities. The main pork processors are Farmers Choice, and other small processors in Nairobi, Nakuru, Njoro and Eldoret. Most processors source carcasses from Ndumboini and Kabati slaughter houses with the exemption of FC. Large pork butcheries like Gilani’s in Nairobi and Nakuru and Prime cuts in Village market also fall under the category of processors since they deal with both processed and fresh pork products. High mechanization technology is employed by processors including cold rooms, refrigerated transport trucks and processing equipment to differentiate cuts for optimum prices.

Marketing

Pork marketing is done at 4 levels; at the farm gate for live pigs, at the abattoirs for slaughtered pigs, at the butcheries, specialized pork eateries and as processed products. The bulk of pork products are sold through butcheries and eateries that constitute the informal markets. Farmers sell pigs at slaughter houses and at the farm gate. Following slaughter, pig producers pay for the slaughter fees in kind by giving up the pork heads, and intestines; especially in Kenol-Kabati and Ndumboini. Since the market demands for lean pork, a slaughtered pig is skinned to trim off the fat.

A distinct market exists in institutions and export markets that demand certifications for food products; these include hospitals, schools, hotels and international organizations. Failure by most abattoirs to meet certification standards such as HACCP has made this market a monopoly of Farmers Choice and other processors.

Many Commercial farmers are putting up their own slaughter slabs, in response to the few abattoirs. The requirements include: Land Title deed, approved plan by local authority, NEMA environment impact assessment, change of land use for commercial purposes from the county authority, licence by the PS to construct the slaughter and annual licence by Vet department, and single business permits to establish a slaughter house. National regulatory agencies such as NEMA, Ministry of Livestock, Local County, Public health are key licence providers. Government meat inspectors are readily available to inspect slaughtered pork for public consumption.

Proper records are the basis of good farm/enterprise management.

It is a good management practice to keep records. By keeping records, a farmer is able to:

- Track the performance of individual pigs; identifying performers from those that haveproblems

- Trace how much is being spent and earned by the enterprise

- Identify animals for use as Sows and Boars (breeding stock)

- Compare the performance of the enterprise with that of other farmers

- Identify which pigs have health and fertility problems

- Identify weaknesses in management and take corrective action.

- Compare the performance of pigs with standard production goals.

FAO, 2009. Farmer's Hand Book on Pig Production (For the small holders at village level)

FAO. 2012. Pig Sector Kenya. FAO Animal Production and Health Livestock Country Reviews. No. 3. Rome.

Driving the pig sector – pork value chain report. Pdf (

Kari information bronchure series/46/2008. Piglet management for improved pig production

Piggery farming pdf department of animal husbandry and vetinary services, Sikkim

Pigs –guide to small scale pig farming pdf

Pig management manual: Ensuring appropriate husbandry practices for profitability. Pdf

Piggery Production Manual: How to Rear Pigs using The Deep Litter System (DLS) or Fermented Bed Technology (FBT). Africa Innovations Institute, Kampala. AprII 2016